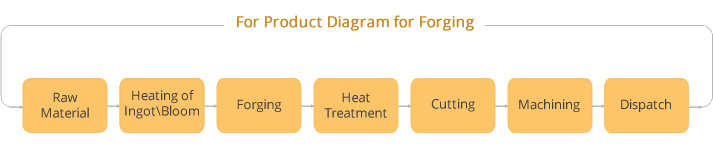

Note : Click on desired Process to view detailed specification.

Our manufacture of Heavy Forging is based Hydraulic press 4500 MT accompanied with Manipulator & 60 HT.

After receiving steel from manufacturer, visual and dimensional check of raw material is done. The colour codes are applied as per the colour coding scheme to every unit of raw material. The colour coding scheme helps to track the material during the manufacturing process. The test certificate from suppliers for raw material is reviewed.

Thereafter, chemical and physical testing of each material is done. The different types of raw material are given lot number and details such as source of supply heat number, supplier's certificate number, company's lot number are decided. Internal Granule Corrosion testing and ultra-sonic testing is done. Marking and cutting the materials are stamped with lot number for identification. The manufacturing division raises requisition slip for material they want to use in their process. The material is issued indicating the lot number. The required material's length and weight are verified. The raw materials, which are in shape of long rods of various diameters, are cut with the use of bandsaw cutting machines.